Grooved electrodes for high-power-density fuel cells

Posting date on solidfuturism: February 1st 2024

Published date: May 25th 2023

Authors: ChungHyuk Lee,2, Wilton J. M. Kort-Kamp, Haoran Yu, David A. Cullen, Brian M. Patterson5, Tanvir Alam Arman, Siddharth Komini Babu, Rangachary Mukundan, Rod L. Borup & Jacob S. Spendelow

DOI: https://doi.org/10.1038/s41560-023-01263-2

Abstract composer: Seyed Amirhosein Mirsadri

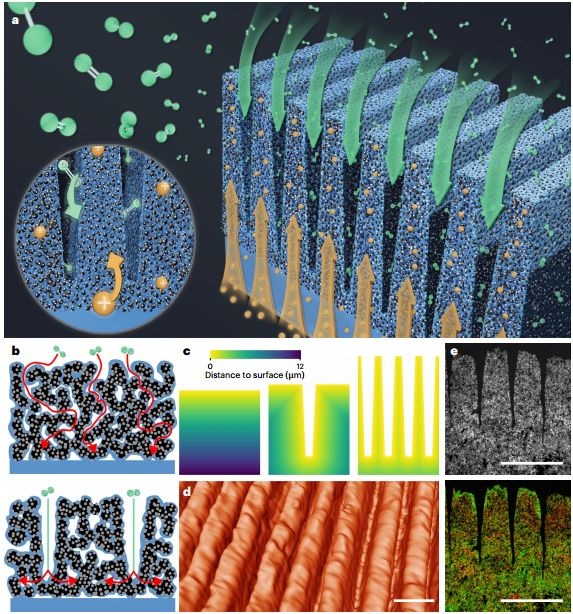

Nowadays, more people are familiar with fuel cells and exploiting carbon supported Pt catalysts for oxygen and hydrogen transfer are of scientist interests. Therefore, because of the high demands for low and high duty vehicles, it is need for more sustainable, durable, compact and humidity resistant fuel cells which are also low cost. Scientists recently come across with a solution of designing the new arrangement and physically changed conventional electrodes. How? they just studied about making or etching grooves with a designed pattern into modified membrane electrodes. The goal was comparing the transfer and reaction rate ratios of the two flat and grooved membrane electrodes. These membranes and carbon supported materials are usually modified with ionomers, these surface binded molecules are responsible for adsorbing and transferring H and O atoms throughout the membranes for better reactions. Therefore, it is believed that when these molecules are getting larger amounts and become saturated in the surface the efficiency will be improved but it is wrong. To answer this hypothesis, we must first dive into the macromolecular form of the surface with TEM imaging instruments.

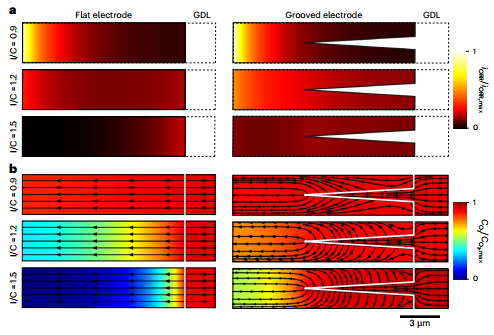

These surfaces have gotten some pores in all around them even the flat ones. The flat ones also got these pore that can adsorb O and H atoms but the path is so meandrous, they are so lengthy with much thin diameters that can increase the transfer resistance. To that end, the grooved ones made it easier for receiving the adsorbed gas atoms. Therefore, saturating the ionomers in the surface could fill these pore areas. Moreover, a value and relation between the ionomers and carbon support was defined as follow: Ionomer/Carbon amount. The flat electrodes showed a fixed optimum amount of 0.9 which by increasing this amount the transferring efficiency will be decreased notably. But in reverse, the grooved ones depicted an expected proper efficiency of oxygen/Hydrogen transferring and oxygen reduction reaction rates (ORR rates) with I/C of 1.2 and 1.5. These experiments undergo impedance spectroscopy and current limitation studies proved that grooved ones had better influence on transferring atoms with I/C=1.2 with two different conditions, helox (79% He, 21% O2) and normal atmosphere.

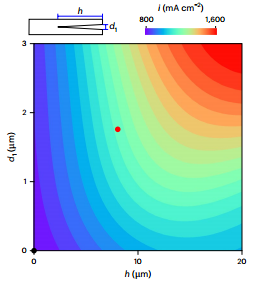

Is ORR rate uniformly increases with grooved electrodes? Well, because these studies are very complex and practically can’t be reached in in situ, the experiments were pursued under simulation conditions. The simulations showed that there are no effects detected for flat electrodes with I/C = 0.9, but grooved ones depicted the increasing amounts of the efficiencies upon I/C = 1.2 or 1.5 that is due to increasing of transporting atoms. The durability and corrosion resistancy were studied with accelerated stress test (AST) with 500 cycles of applied 1-1.5 v electricity in the condition of hydrogen and nitrogen atmosphere. Therefore, the grooved electrodes showed more resistancy than flat ones but both of them were experienced some amounts of corrosion for instance. The grooved ones also depicted a constant efficiency under more and less humidity that makes it good candidate for exploiting in a wide range of weather conditions. Like other newly published articles, this paper is also studying the deepness, the width of the groove openings and mechanical stability with machine learning approach.

This method suggested that the efficiency will be increased upto 60% by making more deeper grooves and the mechanical stability will be decreased when the surface is being more porous. The electrode and membranes were designed and fabricated by plasma technology with UV etch patterning and be characterized by TEM and EDX that was employed in the electro impedance spectroscopy analysis.

klsjuidhfasdgh.png)

klsjuidhfasdgh.png)

klsjuidhfasdgh.png)

klsjuidhfasdgh.png)

klsjuidhfasdgh.png)

klsjuidhfasdgh.png)

klsjuidhfasdgh.png)

klsjuidhfasdgh.png)